If just needs 3000-6000 tons copper rod per year, usually there are two ways to do based on different raw materials.

1)Raw material is clean copper cathode. Then Copper rod up casting machine is suitable.

The upcasting line is used to produce the long and bright oxygen-free copper rod.

Melting Furnace melt the copper cathode into liquid, the liquid keeps off the air by charcoal or graphite flake in case of be oxidation.

The holding furnace keeps the copper liquid temperature in 1150℃±10℃, the casting machine crystallizes the copper liquid quickly, then continuously produces copper rod.

Through this way, the Copper rod electrical resistivity can keep small or same as 0.10724.

After produce 2.6mm from Copper Rod Breakdown Machine, the smaller sizes can be used for input wire of multi wire drawing machine.

2) Raw material is copper scrap, production progress will be more complicated.

Firstly, Electrolytic copper, the copper content is above 99.95%. Go directly to the upcating line furnace.

Secondly, First-grade recycled copper or scrap copper with a copper content of not less than 98% (a small amount of raw materials with a copper content of 96% can be mixed),

and all raw materials must not have plating (including tin plating, nickel plating, etc.). With PVC or other coverings, the surface of the raw material should be clean and shiny. Must be sorted manually.

Except for the bright copper wires of very good quality, which can directly enter the upcasting furnace, other raw materials need to be refined in the tilting furnace.

Finally, The ratio of raw materials: electrolytic copper and refined copper liquid 5:5, and further mix according to the raw materials.

Main machine for each step as below:

2-1)Refining furnace: Remove impurities in copper scrap

2-2)Special transport devices which transport clean copper liquid from refining furnace to upcasting line.

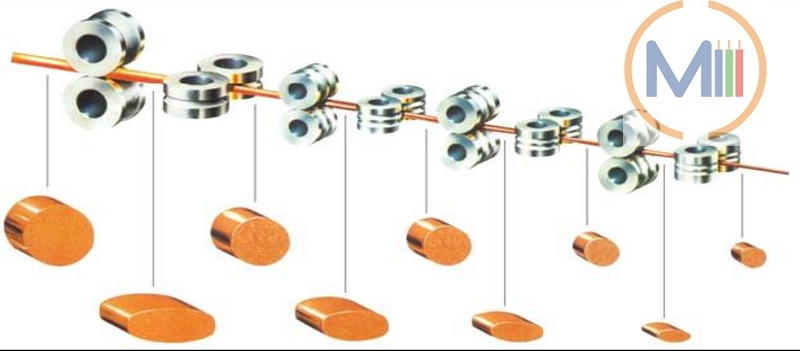

2-3)Copper rod upcasting line will produce 17mm copper rod

2-4) Rolling machine to produce 8mm copper rod from 17mm to improve the quality and mechanical property of copper which makes drawing easier

3)Use professional testing devices to double check the copper rod 8mm quality.

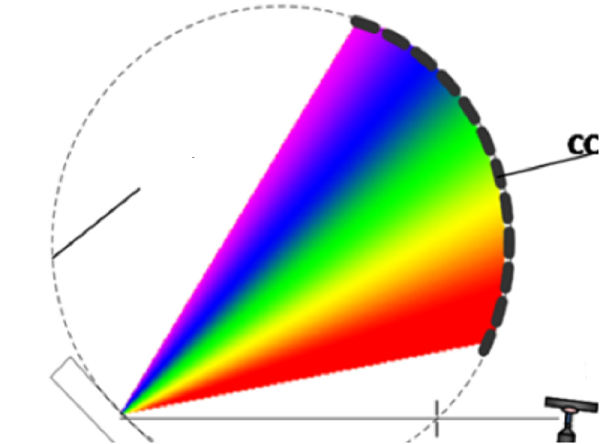

3-1)Full Spectrum Direct Reading Spectrometer: can accurately determine the content of C, P, S, N and various elements in non-metallic elements

3-2)Oxygen Analyzer

3-3)Intelligent Digital Resistance Bridge for copper wire

3-4)Torsion testing machine

3-5)Microcomputer controlled servo universal testing machine

(mainly used for copper or alu wire tensile, compression, bending, shearing )

If need know more details, send mail to sunman@mentorsmachinery.com

Please do not forward the above articles without our permission.