How to Produce New Energy Automotive Cable

1. New Energy Automotive Cable types

1.1 Low voltage automotive cable

1) Provide power and grounding for electrical equipment.

2) Combine with some switches and relays on the car to realize the functional control of electrical equipment.

3) Realize signal transmission between sensors, switches, actuators and controllers.

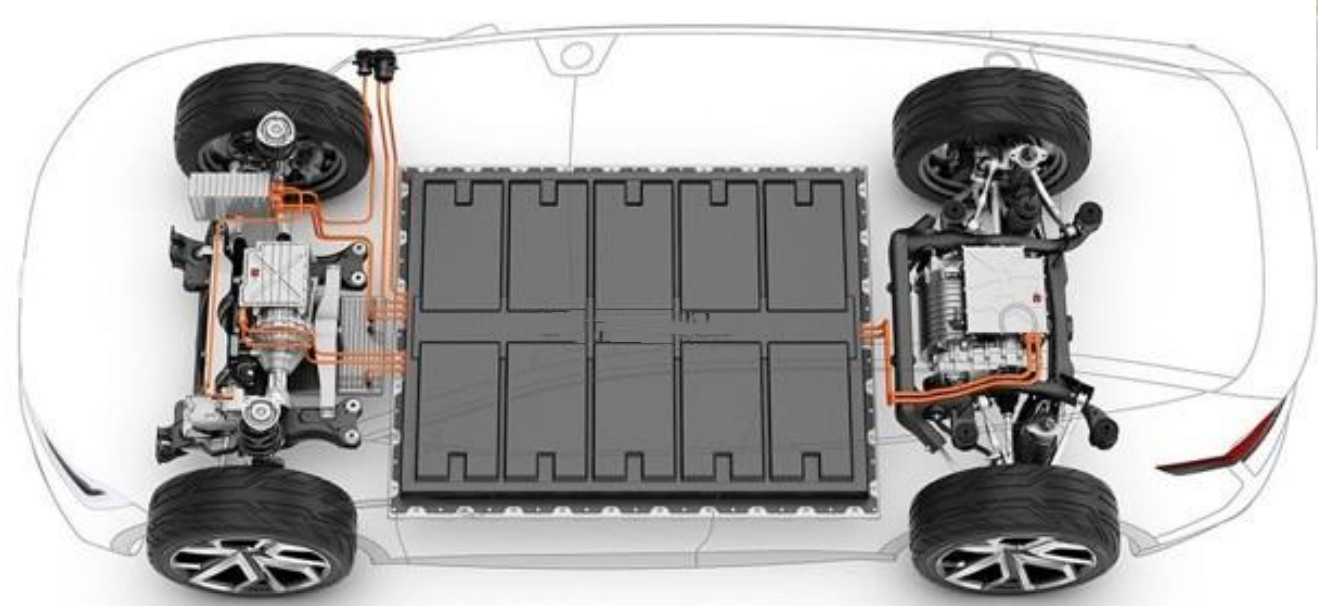

1.2 High voltage automotive cable

Connect the power battery and power motor, charger, DC/DC and electric air-conditioning compressor and other high-voltage components, responsible for high-voltage power transmission and distribution.

cable size details as below:

a)Power line: 16,25,35,50mm2

b)Electric accessory: 2.5,3,4,6mm2

c)AC charger: 2.5/4/6mm2

d)DC charger: 25,35,50,70mm2

2.Performance requirements of high-voltage cables

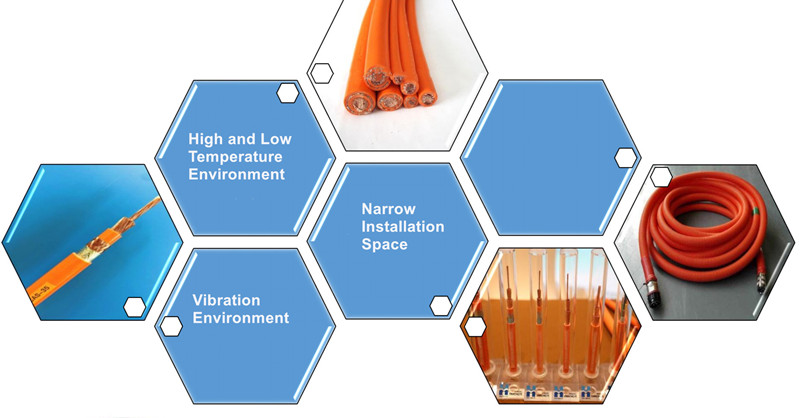

2.1 Complicated environment

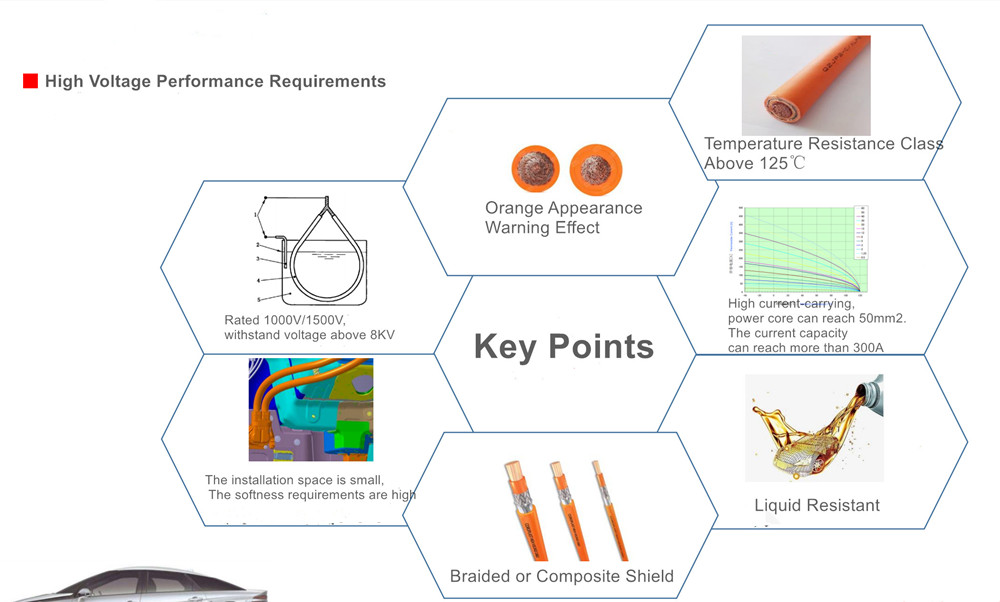

2.2 key points for high voltage performance

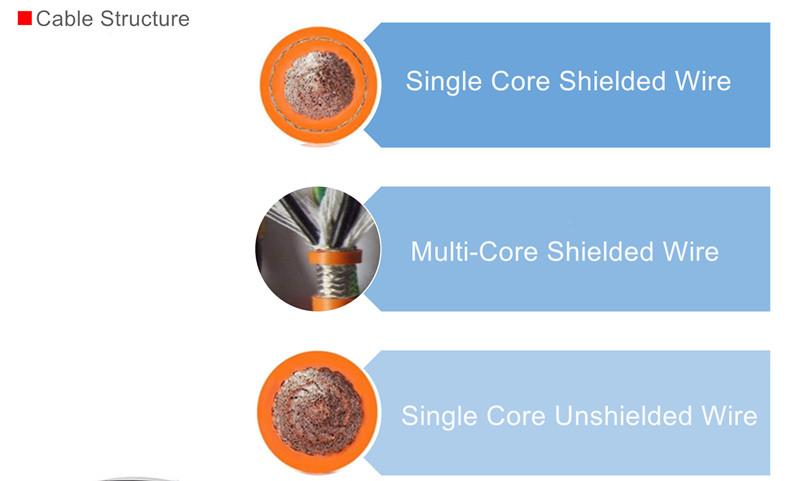

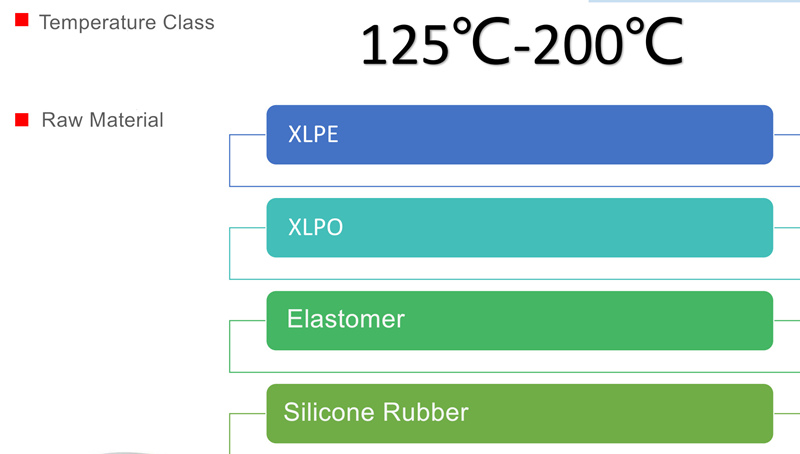

2.3 New Energy Automotive Cable Structure and Temperature Class

3. New Energy Automotive Cable Application

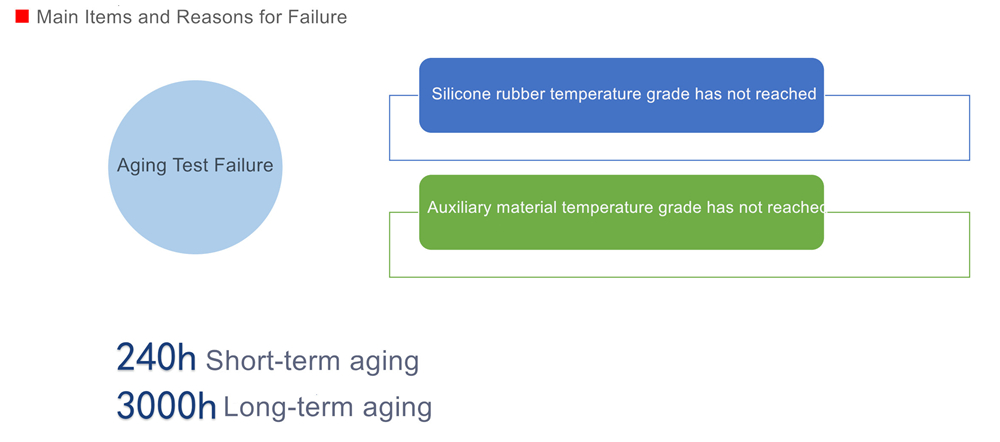

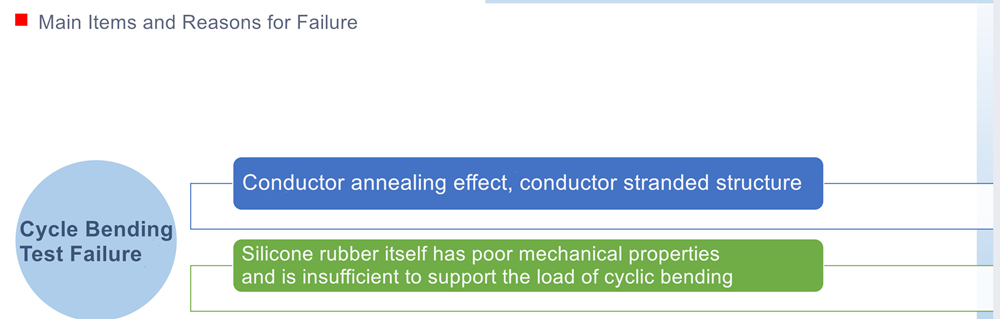

3.1 Main Items and Reasons for Testing Failure

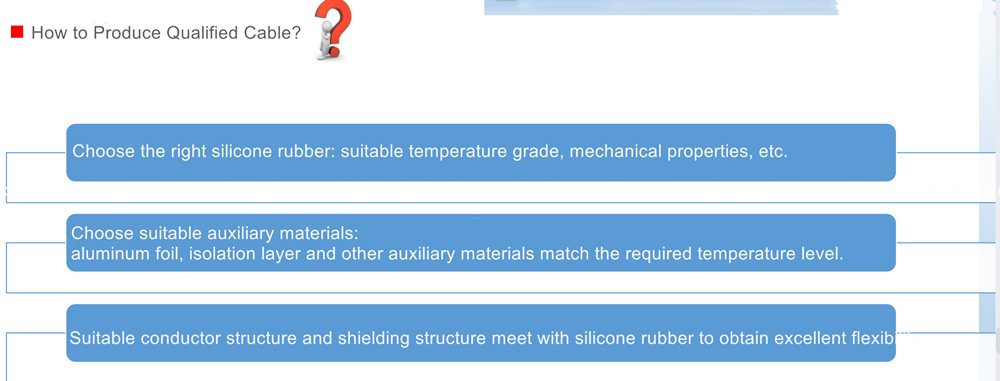

3.2 How to produce qualified New Energy Automotive Cable

Note: Above data is from Shanghai national wire and cable quality supervision and inspection center(TICW)

Please do not forward the article without our permission.