Wire drawing lubricant used for wire drawing will affect the wire drawing process.Today Mentors shares some knowledge about lubricant.Hope this can be of some help to you.

1.Effect of lubricant

1.1 Lubricate effect

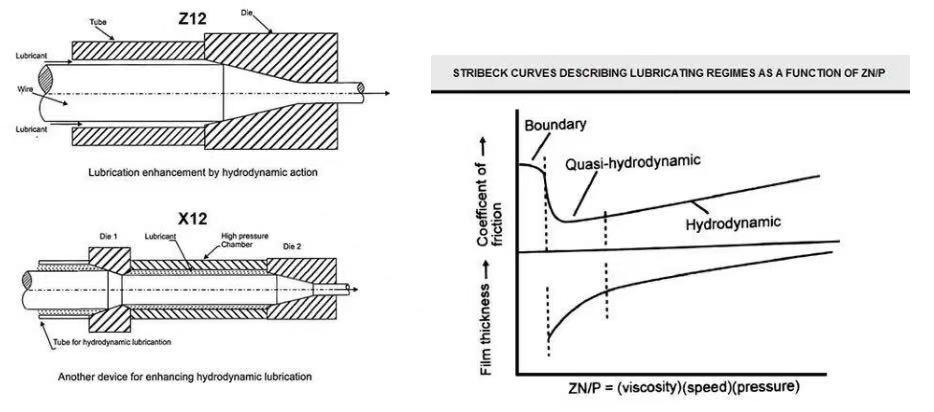

1.1.1 Between the deformed metal and the die, a layer of lubricating film is connected to restrain the die and the wire from directly fighting and bonding.

1.1.2 The friction coefficient is low, thus eliminating the energy consumption and processing times, and extending the service life of the die.

1.2 Cooling effect

1.2.1 The use of cooling lubricant can reduce the temperature of the wire and the die hole.

1.2.2 It can prevent the temperature of the wire too high to cause oxidation discoloration, and improve the wire speed.

1.3 Washing effect

1.3.1 In the drawing process, the fine metal dust is constantly incubated.

1.3.2 The wire drawing lubricant keeps washing the die hole to eliminate the effect of metal dust in the die hole.

2.Influence factors of lubricant in wire drawing

2.1 Concentration

2.1.1 The wire drawing lubricant has high concentration, which improves its lubricant effect.

2.1.2 The friction coefficient between the metal wire and the die hole wall is small.

2.1.3 The corresponding friction force is also reduced, and the tensile force falls accordingly.

2.1.4 The concentration is too large to take the metal chips of the die hole away, which can cause poor appearance quality of the wire.

2.1.5 The viscosity of the lubricant is also increasing.At the same time, the washing effect will be reduced.

2.1.6 Because of the high concentration of the lubricant, the metal chips will not precipitate but suspended in the lubricant, which affect lubricate.

2.2 Temperature

2.2.1 The high temperature also affects the strength of the grease lubricant film.

2.2.2 When the temperature is too high, the viscosity of the lubricant increases, and it is hard to stretch.

2.2.2 The high temperature of the wire drawing lubricant will lead to its cooling effect loss, which increases the temperature of the metal wire and the mold.

2.2.3 It can also cause the oxidation and discoloration of the wire, reduces the life of the mold, and affect the strength of the grease lubricant film.

2.3 Cleanliness

2.3.1 Lubricant mixed with acid substances will cause the lubricant stratification.

2.3.2 The increase of alkali content in lubricant will cause damage to the corrosion of the stretched metal wire.

2.3.3 There are solid impurities in the lubricant, which affect the configured lubricant system, resulting in insufficient lubricant fluid supply, and reduce the role of the lubricant.

3.Requirements for lubricant

3.1 Good adhesion.The lubricant can effectively adhere to the appearance of the drawn wire.

3.2 It can withstand the high pressure between the wire and the mold, and has good thermal stability.

3.3 No corruption.

3.4 Good cooling results.

3.5 No irritating odor.

3.6 Easy to undo after drawing.

4.Drawing lubricanttips

4.1 Single die groove evacuation lubricant

4.2 It is decided that the circulating water in the die tank plays a cooling role.

4.3 It is used for a single wire drawing machine or a non-sliding accumulator multi-die wire drawing machine, which has no limit on the form of the lubricant.

4.4 Because the mold groove is open, the lubricant environment can be directly observed, which is easy to mediate. But it is easy to stain the configuration and the garden.

4.5 Immersion lubricant

4.6 It is suitable for sliding continuous wire drawing machine with strong emulsion and liquid lubricant.

4.7 The wire drawing lubricant is loaded in the special groove of the wire drawing machine, and the drum, line and mold are immersed in the lubricant.

4.8 The layout is simple, and the continuous lubricant and cooling of the mold, drum and wire can be guaranteed.

It’s all for today’s sharing. If you have any different opinions,welcome to contact us.

NOTE:All rights reserved, Reprinting is prohibited without permission.