Wire drawing is a metalworking process used to reduce the cross-section of a wire and increase wire length by pulling the wire through a single or series of drawing dies.

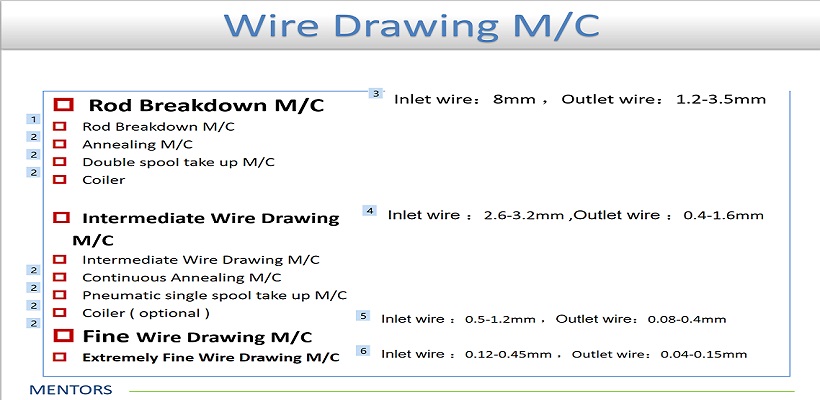

1. Based on different input and output wire size, there are three types.

1.1Rod Breakdown Machine

1.2Intermediate Wire Drawing Machine

1.3Fine Wire Drawing Machine

Wire drawing machines used in the wire and cable industry like these kind of name.

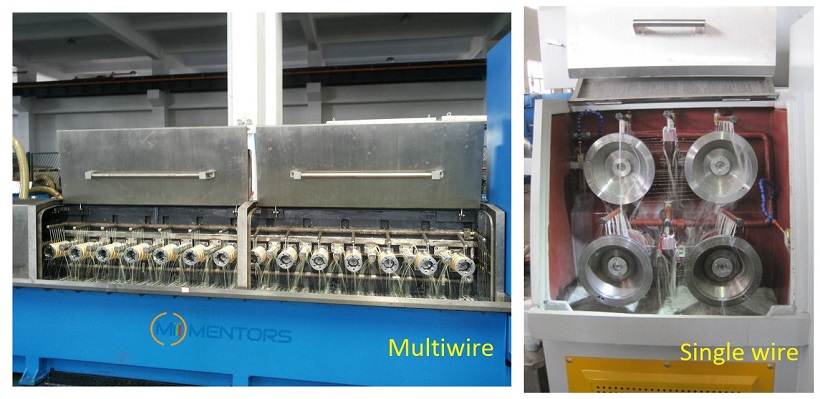

2.Based on the wire quantity, there are two types.

2.1 Multiwire drawing machine (2 wires, 4 wires, 8 wires, 16 wires etc)

2.2 Single wire drawing machine.

These type name is popular for copper wire drawing machine.

3.Based on the wire raw material

3.1Copper wire drawing machine

3.2Aluminum wire drawing machine

3.3Copper alloy wire drawing machine

3.4Aluminum alloy wire drawing machine

3.5CCA,CCS, SPC wire drawing machine

3.6Steel wire drawing machine

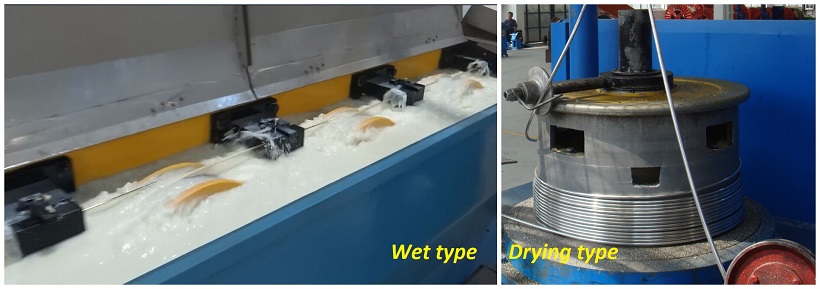

4.Based on the lubrication type

4.1Wet type wire drawing machine: immersed type or spray type wire drawing machine。

4.2Drying wire drawing machine: headstand wire drawing machine, straight line wire drawing machine and pulley type wire drawing machine. Which mainly used for drawing ferrous metal.

There are many applications for wire drawing, including electrical wiring, cables, magnetic wire and enameled wire.

Although similar in process, drawing is different from extrusion,

because in drawing the wire is pulled through die instead of pushed.