When you start produce the silicon cable,besides EXTRUDER, don’t forget Rubber Mixing Mill, which will help produce the silicon raw material. Details as below:

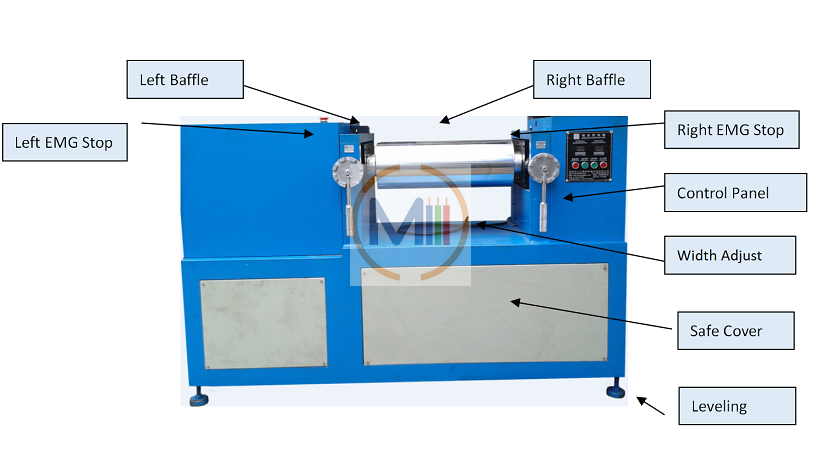

SY-360L Double Drum Rubber Mixing Mill

Usage: it’s used for plasticization through mixing the rubber and the vulcanizing agent to press and release the tablets.

Main spec:

1. Mixing capacity: 5-30kgs

2. Roller temperature: room temperature~tap water ℃

3. Heating method: friction heating

Cooling method: internal tap water cooling

4. Temperature accuracy: no requirement

5. Drum speed: fixed speed (about 15 rpm can be customized with frequency conversion speed adjustment and other speeds)

6. Roller speed ratio: 1:1.27 (other ratio speeds are free to customize)

7. Drum size: ф360mm×L910mm (high hardness surface is plated with hard chrome mirror finish, no sticky material, no delamination)

8. Roller spacing: 0.1~20mm adjustable

9. Safety device: multiple touch-type emergency stop devices (with reverse function, safety first, humanized design, operating workers will always be safe and free of work injuries)

10: Main motor: 37KW (the latest design, mechanical structure adjustment, and the output torque is the same as the traditional process mechanical transmission 45KW, to achieve the purpose of energy saving)

11. Work rate: 37KW

12. Dimension: (L×W×H) 3000×1250×1580mm.

it is much smaller than traditional technology, and space-saving.

13. Roller lubrication: The contact area of the particularly good wear-resistant bearing is larger than the traditional ones. The service life of the copper sleeve has been extended by 2/3.

14. Mechanical structure: steel plate (lighter in weight and smaller in volume than traditional cast iron, with higher mechanical strength and better toughness)

15. Power supply: 380V,50HZ,3Phase or customized

16. Weight: approx 3800kg

If you need to know more details, send mail to sunman@mentorsmachinery.com

Please do not forward the above articles without our permission.